「 投稿者アーカイブ:樹脂プラスチック材料 」 一覧

-

-

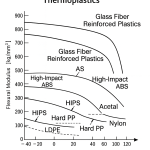

Temperature Dependence of Flexural Modulus in Thermoplastics

The flexural modulus of plastic materials is a critical mechanical property that directly affects product stiffness, deflection behavior, tactile feel, and long-term durability. For applications exposed to wide temperature ranges, a correct understanding of the temperature dependence of flexural modulus is essential for reliable material selection and robust product design. This article reviews the temperature-dependent behavior of flexural modulus in representative thermoplastics and highlights key considerations that are directly applicable to practical engineering and design work. What Is Flexural Modulus? Flexural modulus is a measure of a material’s resistance to bending deformation. A higher flexural modulus indicates a stiffer material, …

-

-

Introduction PPS (polyphenylene sulfide) is a high-performance super engineering plastic known for its excellent heat resistance, chemical resistance, and dimensional stability. It is widely used in high-performance components for automobiles, electrical and electronic devices, and industrial equipment. Demand is particularly increasing for metal replacement applications and EV-related components, driving greater global attention to the PPS market. Market Size Trends (2022–2025 Forecast) 2022: Approx. 142,000 tons (USD 1.9 billion) 2023: Approx. 156,000 tons (USD 2.1 billion) 2024 (estimated): Approx. 171,000 tons 2025 forecast: Approx. 188,000 tons (around USD 2.5 billion) The CAGR (compound annual growth rate) for 2022–2025 is approximately 5.5%. …

-

-

Introduction PTFE (polytetrafluoroethylene) is a high-performance fluoropolymer produced by the polymerization of tetrafluoroethylene (TFE) monomers. Owing to its extremely low coefficient of friction, excellent chemical resistance, broad thermal stability (–200°C to +260°C), and superior electrical insulation properties, PTFE is widely used across industries—from advanced manufacturing to household products. This report provides a detailed analysis of the PTFE market in 2025, focusing on price trends, demand structure, application segments, and the competitive positioning of major manufacturers. Global Market Size and Growth Forecast (2022–2025) The global PTFE resin market has evolved as follows: YearGlobal Market Size (Billion USD)Growth Rate (CAGR) 2022Approx. 3.01— …

-

-

Global Iodine Market Report 2025: Market Size, Price Trends, Key Applications, and Future Outlook

Introduction Iodine is an essential element used in a wide range of applications, including pharmaceuticals, X-ray contrast media, disinfectants, feed additives, and as a key raw material for polarizing films in liquid crystal displays (LCDs). Japan is one of the world’s leading iodine producers, alongside Chile and the United States, and plays a major role in the global market. Global Iodine Market Size (2022–2025) 2022: Approx. USD 1.1 billion 2023: Approx. USD 1.23 billion 2024 (estimated): Approx. USD 1.35 billion 2025 forecast: Approx. USD 1.42 billion (CAGR: 6.5%) Stable demand from the pharmaceutical/healthcare sector and electronic materials (LCD-related applications), combined …

-

-

Perovskite Solar Cell Market Report 2025: Market Size, Price Trends, and Commercialization Outlook

Introduction Perovskite solar cells are attracting global attention as next-generation photovoltaic technology with strong potential for high efficiency and low manufacturing cost. Using organic–inorganic hybrid perovskite crystals, they can achieve power conversion efficiencies exceeding 25%, comparable to conventional silicon solar cells. Their thin-film structure, lightweight nature, and ability to conform to curved surfaces have opened pathways for applications in building-integrated photovoltaics (BIPV), IoT devices, and more. Global Market Growth (2022–2025 Forecast) 2022: Approx. USD 200 million (demonstration stage) 2023: Approx. USD 320 million (early commercialization) 2024: Approx. USD 560 million (estimated) 2025 forecast: USD 900 million–1 billion (CAGR: 45%+) Although …

-

-

Acrylic vs AS Resin: Differences in Transparency, Durability, and Cost

Acrylic (PMMA) and AS Resin (Acrylonitrile-Styrene Copolymer) are popular thermoplastics known for their transparency and moldability. However, they differ significantly in durability, UV resistance, and applications. KEY POINT Acrylic is ideal for outdoor applications with excellent clarity and UV resistance. AS Resin offers better impact resistance and lower cost, but it is less durable under sunlight. What is Acrylic? Acrylic (PMMA) is a clear thermoplastic with high light transmittance (up to 92%) and excellent weatherability. Commonly used in signage, light covers, and displays, it is lightweight and resistant to UV degradation. What is AS Resin? AS Resin is a copolymer …

-

-

POM (Polyoxymethylene) Resin Pellets: Properties, Applications & Major Global Manufacturers

What is a POM Pellet (Polyoxymethylene Pellet)? POM (polyacetal/polyoxymethylene) offers several advantages: high rigidity and hardness, low friction coefficient, excellent wear resistance, high heat resistance, low water absorption, superb dimensional stability, good electrical insulation, greater creep resistance than nylon, high gloss and crystallinity, and low smoke emission. Common applications include gears, bushings, screws, nuts, washers, and spacers. POM is available in two types: homopolymer and copolymer. Generally, homopolymers exhibit higher crystallinity and superior thermal and mechanical properties compared to copolymers because of the continuous “−CH₂O−” backbone composed of identical monomer units. In contrast, copolymers contain “C−C” linkages in the backbone, …

-

-

Overview of Leading Nylon (Polyamide) Resin Manufacturers and Grades

For detailed information on polyamide (nylon) resins—covering characteristics, applications, heat resistance, degradation, structure, flame retardancy, toxicity, and more—please visit our comprehensive page below. Polyamide resins (nylon) are used in tire cords, rubber hoses, engine components, airbags, and are available in various types like PA6, PA10, PA66, PA9T, etc. Explore our Polyamide (Nylon) Resin Overview » Asahi Kasei – Polyamide (PA) Resin “LEONA™” LEONA™, launched in May 1972, is Asahi Kasei’s flagship PA66 resin. Unique in Asia, Asahi Kasei handles every production step—from monomers like cyclohexanone and adipic acid to fibers (e.g., tire cords, airbags) and final resin. Its annual capacity …

-

-

Overview of Leading ABS Resin Pellet Manufacturers

ABS Resin Pellets ABS (Acrylonitrile-Butadiene-Styrene) resin pellets are produced through copolymerization and pelletized via extrusion. Known for excellent chemical resistance (alkaline and acidic), glossy finish, dimensional stability, and ease of processing, ABS is a balanced engineering plastic suitable for various applications. Below is a list of major ABS pellet manufacturers and their product lines. Techno UMG – “Techno ABS”, “Techno MUH” A leading Japanese supplier of styrenic resins, producing over 250,000 tons of ABS per year. Visit Official Website Asahi Kasei – “Stylac” Offering a wide range of grades for automotive, appliance, and OA equipment applications. Visit Official Website Denka …

-

-

Resin & Plastic Materials Environmental Association

The Resin & Plastic Materials Environmental Association is a specialized platform dedicated to the dissemination of technical and environmental knowledge concerning resins and plastics. This site serves as a knowledge hub for professionals engaged in manufacturing, design engineering, materials science, procurement, R&D, production, and environmental management. It aims to support the resolution of material-related challenges and foster informed decision-making in both industrial and academic settings. Topics covered include fundamental and advanced knowledge of plastic materials, classification and selection strategies, material properties and specifications, application fields, supplier directories, catalog databases, environmental compliance, IoT/IT collaboration, industry exhibitions, and emerging technologies. About the …