The flexural modulus of plastic materials is a critical mechanical property that directly affects product stiffness, deflection behavior, tactile feel, and long-term durability. For applications exposed to wide temperature ranges, a correct understanding of the temperature dependence of flexural modulus is essential for reliable material selection and robust product design.

This article reviews the temperature-dependent behavior of flexural modulus in representative thermoplastics and highlights key considerations that are directly applicable to practical engineering and design work.

Contents

What Is Flexural Modulus?

Flexural modulus is a measure of a material’s resistance to bending deformation. A higher flexural modulus indicates a stiffer material, while a lower value corresponds to greater flexibility.

In polymeric materials, increasing temperature enhances molecular mobility, which generally leads to a reduction in flexural modulus. The extent and pattern of this decrease strongly depend on factors such as crystallinity, amorphous structure, glass transition temperature (Tg), and the presence of reinforcing fillers.

Relationship Between Flexural Modulus and Temperature for Various Plastics

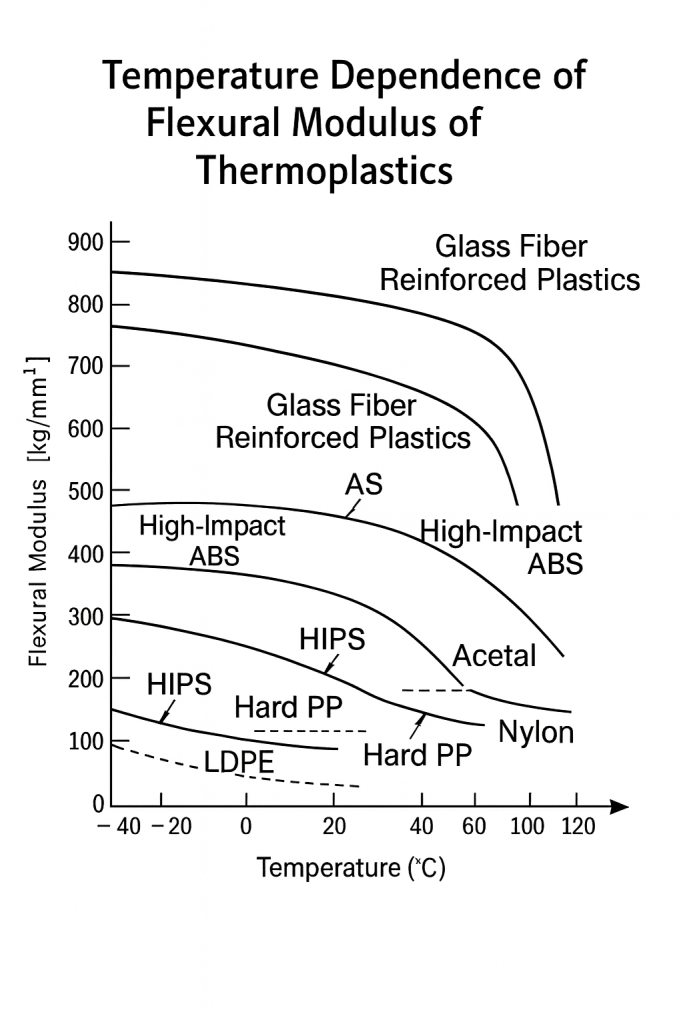

As illustrated in the figure, the temperature dependence of flexural modulus differs significantly among plastic materials.

- Glass fiber–reinforced plastics (e.g., GF-reinforced AS, GF-reinforced CPPS)

These materials maintain a high flexural modulus even as temperature increases, exhibiting relatively gradual stiffness degradation. - Unreinforced engineering plastics (AS, ABS, PC, etc.)

High stiffness is maintained in the ambient temperature range; however, a sharp reduction in modulus occurs near the glass transition temperature. - Commodity plastics (PP, LDPE, HIPS, etc.)

These materials show comparatively low flexural modulus even at low temperatures and become increasingly flexible as temperature rises.

In particular, polycarbonate (PC) and heat-resistant ABS grades retain moderate stiffness up to elevated temperatures, but exhibit a pronounced modulus drop in the range of approximately 80–120 °C. This behavior is closely associated with glass transition phenomena.

Characteristics by Material Category

The temperature dependence of flexural modulus can be broadly summarized by material category as follows:

- Glass fiber–reinforced plastics

High stiffness and low temperature sensitivity; well suited for structural parts and applications requiring dimensional stability. - Amorphous plastics (AS, ABS, PC, etc.)

High stiffness below Tg, followed by a rapid decrease in modulus near the glass transition region. - Crystalline plastics (PP, PE, Nylon, etc.)

Modulus changes more continuously with temperature, but overall stiffness levels are relatively low.

Practical Design and Material Selection Considerations

When evaluating the temperature dependence of flexural modulus, the following practical points should be considered:

- Always confirm the effective modulus within the actual service temperature range.

- Do not rely solely on room-temperature data, as material performance can change significantly at elevated or low temperatures.

- The presence or absence of glass fiber reinforcement has a major impact on stiffness stability.

- For appearance and decorative parts, special attention should be paid to deformation and deflection caused by modulus reduction.

In applications such as glass-replacement components or thin-wall parts, temperature-induced stiffness reduction can lead to vibration, warpage, or noise issues. Careful evaluation is therefore essential.

Conclusion

The temperature dependence of flexural modulus is a fundamental property that directly influences the reliability of plastic components under real service conditions. A material assessment that accounts for temperature variation, rather than relying solely on catalog values, is key to achieving high-quality and robust product designs.

The Resin & Plastic Materials Environmental Association will continue to provide structured, application-oriented insights ranging from fundamental material properties to practical engineering considerations, supporting designers, purchasers, and developers worldwide.