「 Material Properties 」 一覧

-

-

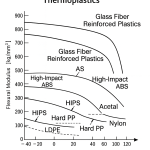

Temperature Dependence of Flexural Modulus in Thermoplastics

The flexural modulus of plastic materials is a critical mechanical property that directly affects product stiffness, deflection behavior, tactile feel, and long-term durability. For applications exposed to wide temperature ranges, a correct understanding of the temperature dependence of flexural modulus is essential for reliable material selection and robust product design. This article reviews the temperature-dependent behavior of flexural modulus in representative thermoplastics and highlights key considerations that are directly applicable to practical engineering and design work. What Is Flexural Modulus? Flexural modulus is a measure of a material’s resistance to bending deformation. A higher flexural modulus indicates a stiffer material, …

-

-

Acrylic vs AS Resin: Differences in Transparency, Durability, and Cost

Acrylic (PMMA) and AS Resin (Acrylonitrile-Styrene Copolymer) are popular thermoplastics known for their transparency and moldability. However, they differ significantly in durability, UV resistance, and applications. KEY POINT Acrylic is ideal for outdoor applications with excellent clarity and UV resistance. AS Resin offers better impact resistance and lower cost, but it is less durable under sunlight. What is Acrylic? Acrylic (PMMA) is a clear thermoplastic with high light transmittance (up to 92%) and excellent weatherability. Commonly used in signage, light covers, and displays, it is lightweight and resistant to UV degradation. What is AS Resin? AS Resin is a copolymer …

-

-

Acrylic vs. Polycarbonate: What’s the Difference?

Acrylic vs. Polycarbonate – What’s the Difference? Acrylic (PMMA) and Polycarbonate (PC) are two of the most widely used transparent engineering plastics. While they are often used in similar applications, such as panels, displays, and glazing, their material properties and performance differ significantly. Here’s a side-by-side comparison to help clarify the key distinctions. Impact Resistance Polycarbonate is extremely impact-resistant—about 250 times stronger than glass. It is often used in bullet-resistant glazing and industrial safety products. Acrylic is less impact-resistant (about 10–20 times stronger than glass) but still suitable for most indoor and outdoor applications where extreme durability is not required. …