For detailed information on polyamide (nylon) resins—covering characteristics, applications, heat resistance, degradation, structure, flame retardancy, toxicity, and more—please visit our comprehensive page below. Polyamide resins (nylon) are used in tire cords, rubber hoses, engine components, airbags, and are available in various types like PA6, PA10, PA66, PA9T, etc.

Explore our Polyamide (Nylon) Resin Overview »

Contents

Asahi Kasei – Polyamide (PA) Resin “LEONA™”

LEONA™, launched in May 1972, is Asahi Kasei’s flagship PA66 resin. Unique in Asia, Asahi Kasei handles every production step—from monomers like cyclohexanone and adipic acid to fibers (e.g., tire cords, airbags) and final resin. Its annual capacity is approx. 76,000 t.

LEONA™ is a high-performance nylon‑66 resin known for its strength, rigidity, heat resistance, and broad grade lineup—reinforced, alloyed, or tailored to meet diverse engineering needs.

Official Website & Data Sheets

UBE – Nylon Types: PA6, PA66, PA12 (“UBESTA”)

UBE offers a range of nylon resins—including PA6, PA66, and PA12—available in injection, extrusion, and tubing grades, serving industrial, automotive, and consumer markets.

Official Website & Product Info

Toray – Nylon Resin “Amilan™”

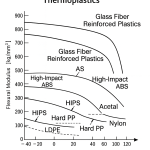

- PA6 & PA66: Excellent mechanical strength, toughness, chemical & oil resistance, self-extinguishing (UL 94 V-0), and heat resistance (80–150 °C).

- PA610: Enhanced flexibility, low temperature impact resistance, and low moisture absorption.

- Copolyamide grades: Offer transparency, flexibility, adhesion, and alcohol solubility.

Official Website & Specifications

Kurare – PA9T Resin “Genesta™”

Genesta™ (PA9T) is Kuraray’s home‑developed engineering nylon. It’s low‑moisture, high‑heat resistant (melting point 306 °C, Tg 125 °C), stable across temperatures, and offers excellent mechanical, molding, electrical, and chemical resistance properties.

BASF – Nylon Resin “Ultramid™”

Ultramid™ includes PA6, PA66, PA66/6 co-polymers, PA610, PA6T/6, and more. Grades range from unfilled to glass-fiber/mineral reinforced, including long-fiber versions. They deliver excellent mechanical strength, stiffness, thermal stability, impact resistance, wear resistance, and processability—ideal for demanding industrial components and electrical insulators.

Official Website & Technical Data