Contents

- 1 What is a POM Pellet (Polyoxymethylene Pellet)?

- 2 Overview of POM Pellet Products & Major Manufacturers

- 3 Mitsubishi Engineering‑Plastics Co., Ltd. – “Iupital™”

- 4 Asahi Kasei – “TENAC™ / TENAC™‑C”

- 5 Polyplastics Co., Ltd. – “Duracon™”

- 6 DuPont – “Delrin®”

- 7 Celanese (Celenese Japan) – “Celcon® / Hostaform®”

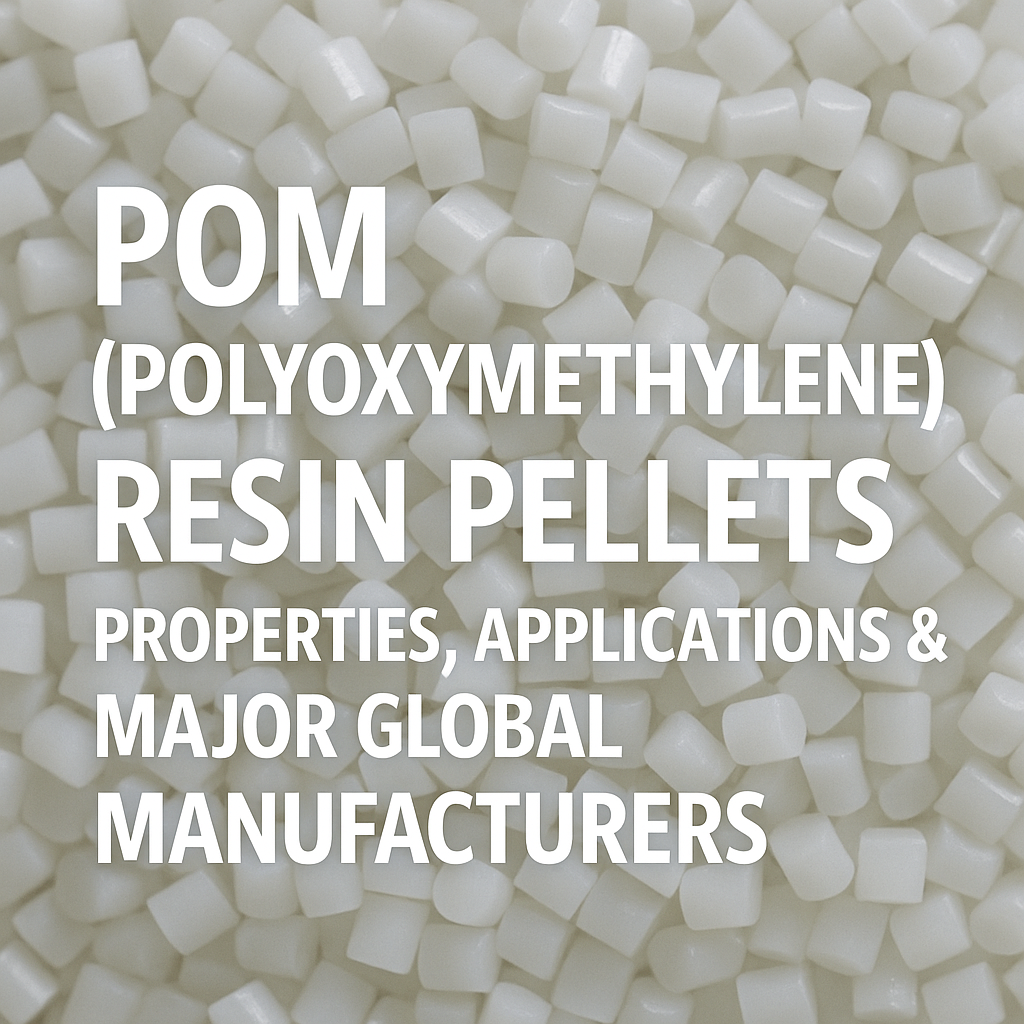

What is a POM Pellet (Polyoxymethylene Pellet)?

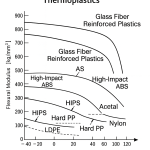

POM (polyacetal/polyoxymethylene) offers several advantages: high rigidity and hardness, low friction coefficient, excellent wear resistance, high heat resistance, low water absorption, superb dimensional stability, good electrical insulation, greater creep resistance than nylon, high gloss and crystallinity, and low smoke emission. Common applications include gears, bushings, screws, nuts, washers, and spacers.

POM is available in two types: homopolymer and copolymer. Generally, homopolymers exhibit higher crystallinity and superior thermal and mechanical properties compared to copolymers because of the continuous “−CH₂O−” backbone composed of identical monomer units. In contrast, copolymers contain “C−C” linkages in the backbone, which can slightly reduce those properties. However, copolymers tend to outperform homopolymers in hydrothermal and long-term heat resistance.

Therefore, homopolymers are chosen when initial strength and fatigue resistance are critical—up to about 10–20 % better than copolymers. But for applications requiring higher long-term continuous operating temperatures, high-strength copolymers are preferred.

Overview of POM Pellet Products & Major Manufacturers

Mitsubishi Engineering‑Plastics Co., Ltd. – “Iupital™”

Iupital™ is a high-performance copolymer-type POM resin developed using proprietary technology and produced in a fully integrated process, from methanol raw materials to finished pellets :contentReference[oaicite:1]{index=1}.

It features balanced mechanical properties (rigidity and toughness), long-term stress durability, self-lubrication, chemical resistance, dimensional stability, wide temperature operability, and good moldability.

F10‑01, F20‑03, F30‑03 (general grades); FG2025, FC2020H (reinforced/fill); LO‑21A, FL2020 (low‑friction); FU2025 (impact‑resistant); ET‑25 (inorganic-filled), etc.

Asahi Kasei – “TENAC™ / TENAC™‑C”

TENAC™ (homopolymer) and TENAC™‑C (copolymer) are unique in that both types are produced via proprietary technology :contentReference[oaicite:2]{index=2}. They exhibit excellent sliding, toughness, fatigue resistance, long-term creep resistance, stability, moldability, chemical resistance, and low VOC emission.

The TENAC™ family includes standard, low-VOC, high-cycle, weather-resistant, filler-reinforced, sliding, and electrically conductive grades. Copolymer “HC” grades combine homopolymer strength with copolymer stability.

A recent addition is the biomass-certified TENAC™ grade (ISCC PLUS certified), offering up to ~50% lower carbon footprint while maintaining performance :contentReference[oaicite:3]{index=3}.

Polyplastics Co., Ltd. – “Duracon™”

Duracon™ is a copolymer POM brand used in a wide range of applications—from mechanical parts (gears, bearings) to appliances (refrigerators, printers), office equipment, and automotive components.

Available in multiple functional grades: low-VOC, high-gloss, conductive, mineral/glass reinforced, anti-creep, high-flow, weather-resistant, and more.

DuPont – “Delrin®”

Delrin® is a homopolymer acetal resin known for low friction, high wear resistance, strength, rigidity, and precision moldability. It covers a temperature range from approximately −40 to +120 °C. Widely used in dental parts, conveyor belts, and medical devices.

Grades include standard, low-viscosity, Teflon-filled (e.g., Delrin 100AF), Kevlar-modified, UV-stabilized, and food-contact variants.

Celanese (Celenese Japan) – “Celcon® / Hostaform®”

Celcon® (POM) offers high crystallinity, excellent wear and fatigue resistance, toughness, solvent and alkaline resistance, and creep resistance. It outperforms homopolymer versions in stability against thermal and oxidative degradation.

Available grades include SlideX™, C 13021/XAP, C 27021, etc.